For OEM suppliers in the racket manufacturing industry, maintaining efficiency, meeting diverse client demands, and managing production costs are critical challenges. A high-efficiency racket hemming machine offers an unparalleled solution to these issues by delivering precision, scalability, and long-term economic benefits. Here's why it stands out as the ultimate choice for OEM suppliers.

1. Meeting the Demand for Low-Cost, High-Efficiency Production

In today’s competitive market, OEM manufacturers must deliver high-quality products at the lowest possible cost. The high-efficiency racket hemming machine optimizes production by significantly reducing manual labor and processing time.

· Streamlined production: The automated hemming process ensures consistent quality and reduces defects, improving customer satisfaction.

· Higher throughput: Capable of handling large-scale production efficiently, it’s ideal for fulfilling bulk orders.

· Cost savings: By minimizing waste and operational errors, the machine lowers overall production costs.

2. Adaptability to Multiple Brands and Specifications

OEM suppliers often need to produce rackets for multiple brands with varying specifications.

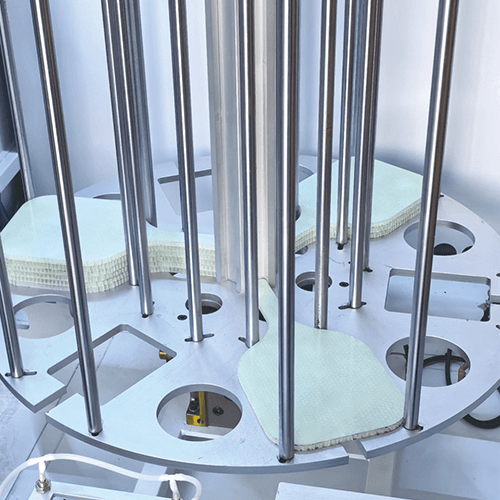

The high-efficiency racket hemming machine is designed with adaptability in mind.

· Multi-brand compatibility: Easily adjusts to different racket shapes and sizes, making it suitable for diverse client demands.

· Precision engineering: Ensures consistent hemming results regardless of the design complexity.

· Quick reconfiguration: Reduces downtime when switching between production lines.

3. Modular Design for Scalability

The high-efficiency racket hemming machine features a modular design, allowing OEM manufacturers to scale production as needed.

· Customizable modules: Add or upgrade components to meet specific production requirements.

· Future-ready: As business grows, manufacturers can expand capacity without replacing the entire machine.

· Versatile applications: Supports a wide range of hemming needs, from beginner to professional-grade rackets.

4. Long-Term Economic Efficiency

Investing in a high-efficiency racket hemming machine is a cost-effective choice for OEM suppliers.

· Durable construction: Reduces maintenance costs and ensures long-lasting performance.

· Consumable savings: Optimized material usage minimizes waste, lowering operational expenses.

· Energy efficiency: Advanced systems reduce power consumption, contributing to further cost savings.

5. Success Story: Boosting Orders and Profits

One OEM supplier who implemented a high-efficiency racket hemming machine reported remarkable results. By automating their hemming process, they increased their production speed by 30%, reduced defects by 20%, and attracted new clients with faster turnaround times. This led to a 25% increase in order volume and a significant boost in overall profits.

The high-efficiency racket hemming machine is more than just a piece of equipment—it’s a comprehensive solution for OEM suppliers. By enhancing production efficiency, accommodating diverse specifications, and ensuring long-term cost-effectiveness, it empowers manufacturers to stay competitive in a demanding market.

For OEM suppliers looking to optimize their operations and boost profitability, investing in a high-efficiency racket hemming machine is the way forward. Its scalability, adaptability, and economic benefits make it an indispensable tool for modern racket production.