In the competitive world of racket manufacturing, precision and efficiency are paramount. Whether it's for tennis, badminton, or squash, the quality of a racket's frame plays a crucial role in its performance. One of the most critical processes in racket production is the hemming of the racket frame. This process involves the careful finishing of the frame’s edges to ensure that it is structurally sound and can securely hold the strings under tension. The Peak Racket Industrial Hemming Machine is a game-changer in this area, offering unmatched precision and efficiency that takes racket manufacturing to the next level.

In this article, we explore how the Peak Racket Industrial Hemming Machine enhances the precision and efficiency of the racket manufacturing process, the technology behind it, its key features, and the overall benefits it brings to the industry.

The Importance of Hemming in Racket Manufacturing

Hemming is a crucial process in racket production, and its quality directly impacts the performance, durability, and aesthetic appeal of the racket. The edge of the racket frame must be hemmed precisely to ensure several things:

Structural Integrity: The hemming process helps in strengthening the racket’s frame. If done poorly, the racket’s frame could become weak, leading to potential breakages or poor string tension.

String Security: A well-hemmed racket ensures that the strings remain tightly secured in the frame, preventing them from loosening or slipping during intense gameplay.

Durability and Longevity: A well-executed hemming process contributes to the racket’s overall durability. Proper finishing prevents wear and tear on the edges, extending the life of the racket.

Aesthetics: Racket frames are often visible to the consumer. A well-hemmed edge enhances the visual appeal of the racket, which is crucial in a market where aesthetics can influence purchasing decisions.

How the Peak Racket Industrial Hemming Machine Enhances Precision and Efficiency

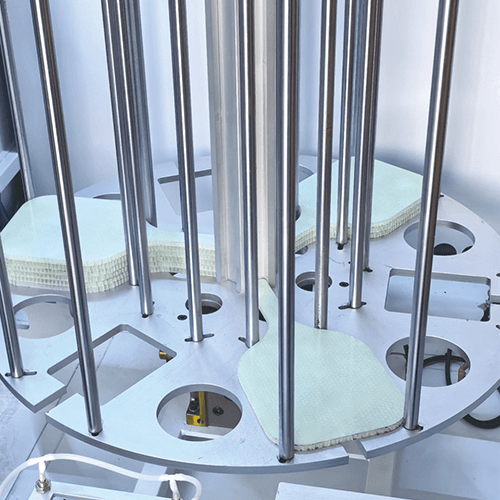

The Peak Racket Industrial Hemming Machine is designed to tackle the complexities of racket hemming with maximum precision and speed. Let’s delve into the ways it enhances both precision and efficiency in the manufacturing process:

1. Automated Precision Control

One of the standout features of the Peak Racket Industrial Hemming Machine is its automated precision control system. This system ensures that the hemming process is carried out with exceptional accuracy. Unlike manual or semi-automatic machines, which are prone to human error, this machine uses advanced sensors and control systems to guide the hemming tool, ensuring that each racket frame is hemmed consistently.

The precision control system can be fine-tuned for different types of rackets, allowing manufacturers to produce frames of various sizes and materials without compromising the quality of the hemming process. By eliminating inconsistencies and errors in the hemming stage, the machine ensures that each racket is built to the highest possible standard.

2. High-Speed Operation for Increased Efficiency

Efficiency in racket manufacturing is key to maintaining competitive pricing while meeting customer demand. The Peak Racket Industrial Hemming Machine significantly boosts production speed by automating the hemming process.

Traditional manual or semi-automatic machines require a significant amount of time for each frame, particularly when adjustments need to be made for different sizes or materials. The Peak Racket Industrial Hemming Machine streamlines this by offering high-speed operation while maintaining precise hemming. The automation reduces human intervention, allowing manufacturers to focus on other areas of production and improve throughput. This not only saves time but also helps reduce labor costs.

3. Customization for Different Racket Types

Racket manufacturing is not a one-size-fits-all process. Different rackets, such as tennis, badminton, or squash rackets, have varying frame designs, sizes, and materials. The Peak Racket Industrial Hemming Machine offers customization options to cater to different types of rackets.

Manufacturers can adjust settings on the machine to accommodate specific requirements, whether it's for a lightweight tennis racket or a heavier squash racket. The ability to adjust the hemming tool for different frame designs ensures that each racket is produced with the optimal amount of precision and care, regardless of its size or complexity.

4. Durable Build and Long-Lasting Performance

Manufacturing equipment must be able to withstand heavy use in a factory setting. The Peak Racket Industrial Hemming Machine is constructed with high-quality materials to ensure durability and long-lasting performance. Built to handle continuous use, the machine’s components are designed to withstand high volumes of production without frequent breakdowns or the need for extensive maintenance.

The robust build of the machine ensures that it can function efficiently over extended periods, reducing downtime and maintenance costs. This makes it a cost-effective solution for manufacturers looking to improve both precision and output.

5. Minimized Material Wastage

Another key advantage of the Peak Racket Industrial Hemming Machine is its ability to minimize material wastage. By ensuring that each racket frame is hemmed with exact precision, the machine prevents unnecessary material loss that often occurs in manual or semi-automatic processes. This is particularly important in racket manufacturing, where materials like high-quality carbon fiber or aluminum are used for the frames.

By reducing material wastage, manufacturers can significantly improve their production efficiency and cut down on raw material costs, making the entire racket manufacturing process more economical and sustainable.

Key Features of the Peak Racket Industrial Hemming Machine

The Peak Racket Industrial Hemming Machine comes with several advanced features that set it apart from other racket hemming equipment:

1. Touchscreen Interface for Easy Operation

The machine is equipped with a user-friendly touchscreen interface that simplifies operation. This allows manufacturers to easily input settings, adjust parameters, and monitor the status of the hemming process. Operators can quickly adapt the machine to different racket types and sizes, ensuring smooth and efficient production.

2. High Precision Sensors

To ensure the highest level of accuracy, the Peak Racket Industrial Hemming Machine is equipped with high-precision sensors. These sensors constantly monitor the machine's operation, making real-time adjustments to ensure that the hemming tool is always positioned correctly, even during high-speed operation.

3. Energy Efficiency

Manufacturers are increasingly focused on energy efficiency, and the Peak Racket Industrial Hemming Machine addresses this concern by consuming less power compared to older machines. Its optimized design ensures that the energy used during operation is maximized, helping reduce overall energy costs and making it a more environmentally friendly option.

4. Customizable Hemming Pressure

The machine offers customizable hemming pressure, which is crucial when working with different materials. For delicate racket frames, lower pressure can be applied, while higher pressure can be used for sturdier frames. This flexibility ensures that the machine can handle various types of rackets without damaging the frame.

The Impact of the Peak Racket Industrial Hemming Machine on the Industry

The introduction of the Peak Racket Industrial Hemming Machine has revolutionized the racket manufacturing industry by enabling companies to produce high-quality rackets at faster speeds and lower costs. It not only ensures superior performance and durability for each racket produced but also helps manufacturers improve their overall efficiency.

The machine’s precision and automation allow manufacturers to scale up production without sacrificing quality, enabling them to meet growing demand while maintaining competitive pricing. Additionally, the ability to reduce material wastage and energy consumption makes it a sustainable option for companies looking to minimize their environmental impact.

Conclusion: Why the Peak Racket Industrial Hemming Machine is a Game-Changer

The Peak Racket Industrial Hemming Machine is a cutting-edge piece of equipment that significantly enhances precision, efficiency, and sustainability in racket manufacturing. With its advanced automation, customizable settings, and high-speed operation, it has become an essential tool for companies looking to produce top-quality rackets while maximizing productivity.

For manufacturers looking to stay competitive in the fast-paced racket production industry, investing in the Peak Racket Industrial Hemming Machine is a smart choice. It not only improves the quality of the end product but also ensures that manufacturers can keep up with the growing demand for high-performance rackets. By embracing the latest technology, companies can enhance their reputation for quality and continue to thrive in a competitive marketplace.